Packaging is one of the most critical components in the eCommerce supply chain. The right packaging strategy can significantly impact both operational efficiency and cost-effectiveness. Traditional packaging methods often result in oversized boxes, excess material usage, and increased shipping costs. These inefficiencies not only drive up expenses but also contribute to environmental waste and customer dissatisfaction due to damaged or inadequately protected products.

Consider the common scenario where a product is packed in an unnecessarily large box. This not only inflates shipping costs but also requires more packing materials, which increases expenses and waste. Additionally, larger boxes take up more space in shipping vehicles, leading to fewer products shipped per load and higher transportation costs. These inefficiencies eat into profit margins and create operational bottlenecks that can be detrimental to a business’s bottom line.

Enter the Advanced Ship-in-Multiple-Boxes Functionality, a cutting-edge solution that leverages advanced algorithms and state-of-the-art hardware to optimize packaging and shipping processes. This solution addresses the common issues faced by eCommerce businesses using platforms like Shopify and BigCommerce and provides a comprehensive approach to enhancing packaging efficiency and cost-effectiveness.

Why Packaging Optimization Matters

Efficient packaging management is crucial for reducing shipping costs and material usage. Traditional methods often lead to unnecessary expenses and operational inefficiencies. Optimized packaging reduces the need for oversized boxes, leading to lower shipping costs and less material waste. This translates to significant cost savings and supports sustainability goals.

Shipping costs are a major expense for eCommerce businesses. By optimizing packaging, companies can drastically reduce these costs. Using right-sized boxes means paying less for shipping and avoiding dimensional weight pricing penalties, where carriers charge based on the size of the package rather than its actual weight.

Accurate and efficient packaging also enhances the overall customer experience. Products that arrive in perfect condition, properly protected, and without excessive packaging leave a positive impression on customers. This can lead to increased customer satisfaction, repeat business, and positive reviews, all of which are essential for long-term success in the eCommerce industry.

The Advanced Ship-in-Multiple-Boxes Functionality

This innovative functionality integrates advanced algorithms and specialized hardware to streamline the packaging process. By accurately measuring product dimensions and optimizing the use of packaging materials, the solution ensures that products are packed in the most efficient manner possible. This results in significant cost savings and improved operational efficiency.

The Advanced Ship-in-Multiple-Boxes Functionality is designed to handle varying levels of packaging needs, from large operations managing millions of units to small businesses with more modest requirements. The technology behind this solution includes the Weight Conveyor Unit, Fixed Volume Measurement Scanner, and Handheld Wireless Volume Measurement Reader, each tailored to different operational scales and needs.

Section 1: Core Benefits At a Glance: Efficiency and Cost-Effectiveness

Eliminating Oversized Packaging: Traditional packaging methods often involve using larger boxes than necessary, leading to higher shipping costs due to dimensional weight pricing. The advanced algorithms in our solution determine the optimal box size for each product, ensuring that you only pay for the space you actually need. This not only reduces shipping costs but also decreases the amount of packing material required.

Reducing Material Usage: By using the precise amount of packaging material needed for each item, businesses can significantly cut down on waste. This not only lowers costs but also supports environmental sustainability. Reduced material usage translates to less waste and a smaller carbon footprint.

Minimizing Labor Costs: The automated measurement and packaging process reduces the need for manual intervention, cutting down on labor costs. Employees can be more productive, focusing on other essential tasks rather than spending time on measuring and packaging products manually.

Enhancing Operational Efficiency: Streamlined packaging processes lead to faster order fulfillment. The quick and accurate measurements provided by the hardware components ensure that products are packed and ready for shipment in less time. This boosts overall operational efficiency and improves throughput, allowing businesses to handle more orders in a shorter period.

Improving Customer Satisfaction: Properly packaged products that arrive in excellent condition contribute to higher customer satisfaction. The reduction in shipping damages and returns due to better packaging ensures that customers receive their orders intact, enhancing their overall experience and fostering loyalty.

As we delve deeper into this article, we will explore the intricate details of this functionality, its components, and the immense benefits it offers to eCommerce businesses using platforms like Shopify, BigCommerce, and Magento. By understanding the technology and its application, businesses can unlock new levels of efficiency, cost savings, and customer satisfaction.

Section 2: The Technology and the Hardware Behind Packaging Optimization

1. Weight Conveyor Unit: The Powerhouse for Large Operations

Handling massive volumes in a fast-paced eCommerce environment demands efficiency and precision. The Weight Conveyor Unit is designed to meet these demands, offering a robust solution for large-scale operations that process millions of units annually.

Why It Matters:

In large operations, every second counts. When your warehouse is processing thousands of orders a day, even minor inefficiencies can add up to significant time losses. Manual measurements not only slow down the process but are also prone to errors, leading to inconsistent packaging sizes, wasted materials, and increased shipping costs. These inefficiencies can hinder your ability to meet customer expectations for fast and reliable delivery.

The Weight Conveyor Unit transforms the way packaging is handled, ensuring speed and accuracy that manual methods simply can’t match. By automating the measurement process, this unit eliminates the variability and errors associated with manual measurements, leading to more consistent and efficient packaging.

Technical Specifications

| Physical Dimensions | |||

|---|---|---|---|

| Length | 60” | ||

| Width | 28” | ||

| Height | 83” | ||

| Weight | 75Lbs to 275Lbs Based on Accessories | ||

| NTEP Certified Measurement Ranges | |||

| Measurement | |||

| MIN. (In) | MAX. (In) | Division | |

| Length | 5.6 | 48 | 0.2 |

| Width | 5.6 | 28 | 0.2 |

| Height | 2.4 | 28 | 0.2 |

| Power Requirements | |||

| Single power source 110-240 V external power supply. | |||

| Object Colors | |||

| Level tables, scales, roller balls and roller conveyors. The background should have a contrasting color for items to be dimensioned. Avoid over polished or glossy surfaces like stainless steel weight platters and flat black paint for best performance. | |||

| Operating Temperature | |||

| 41° F to 104° F (5° C to 40° C) | |||

| Humidity | |||

| Non-condensing | |||

| Mechanical Environment Class | |||

| M1 | |||

| Electromagnetic Class | |||

| E1 | |||

| I/O Ports | |||

| (1) USB type A port (interface to scale). (1) 10/100/100BASE-T Ethernet port (interface to PC). |

|||

Technical Mastery:

Imagine a system that can measure and process items almost instantaneously, significantly reducing the time spent on each package. The Weight Conveyor Unit does just that, with a measurement speed of 0.2 seconds. This rapid processing time ensures that your packaging lines can keep up with high order volumes without bottlenecks.

- Measurement Speed: With a remarkable speed of 0.2 seconds per item, the Weight Conveyor Unit keeps your operation flowing smoothly.

- Capacity Range: Whether dealing with small packages of 60 lbs or larger packages of up to 300 lbs, this unit provides reliable performance across a wide range of weights.

- Precision: Accurate dimensions calculated within 0.2 inches ensure that every package is optimized for shipping, reducing the risk of using oversized boxes.

Features at a Glance:

- Speed and Precision: The ability to measure up to 48” in length and 28” in height within 0.2 seconds.

- Seamless Integration: Interfaces with NTEP-certified shipping scales, providing compliance and accuracy.

- Real-Time Data: A USB operator display shows dimensions, weight, and images, enabling quick decision-making.

- Flexibility: Both automatic and manual operation modes to suit various operational needs.

- Ease of Use: No special alignment is required, minimizing setup time and ensuring smooth operation.

- Connectivity: Static IP or DHCP for network integration, ensuring data flows seamlessly into your systems.

Real-World Impact:

Think about the common issues faced in large-scale packaging operations: manual errors, high labor costs, oversized packages, and inefficient use of space. The Weight Conveyor Unit tackles these issues head-on.

- Reducing Errors: By automating measurements, the risk of human error is virtually eliminated, ensuring consistent accuracy.

- Labor Efficiency: Automation reduces reliance on manual labor, freeing up staff to focus on more critical tasks, thus lowering labor costs.

- Cost Savings: Accurate measurements mean no more oversized packages. This reduces shipping costs and avoids penalties from carriers based on dimensional weight pricing.

- Operational Continuity: Easy setup and low maintenance mean less downtime and more productivity, keeping your operations running smoothly.

- Customer Satisfaction: Precision in packaging translates to fewer damaged goods, reducing returns and increasing customer satisfaction.

By integrating the Weight Conveyor Unit into your packaging process, you can achieve a level of efficiency and precision that manual methods cannot offer. This technology not only streamlines your operations but also enhances your ability to meet customer expectations for fast, cost-effective delivery.

2. Fixed Volume Measurement Scanner: Precision for Mid-Level Operations

For mid-sized businesses, efficiency and accuracy are paramount. The Fixed Volume Measurement Scanner is designed to cater to these needs, offering a versatile and precise solution for operations that handle a diverse range of product shapes and sizes. This technology ensures that every item is measured accurately, enabling businesses to optimize their packaging and shipping processes effectively.

The Need for Precision:

Mid-sized operations face unique challenges where balancing volume with accuracy is crucial. Manual measurements can lead to inconsistent results, material waste, and inflated shipping costs. Moreover, the time-consuming nature of manual processes can slow down overall productivity, impacting the ability to fulfill orders promptly.

The Fixed Volume Measurement Scanner addresses these challenges head-on by providing automated, precise measurements for a wide range of products. This not only reduces errors but also speeds up the packaging process, allowing businesses to handle more orders efficiently.

Technical Specifications

| Physical Characteristics | |

|---|---|

| Camera (WxLxH) | 160 x 138 x 53 mm |

| Full assembly with Stand | 500 x 900 x 1650 mm (camera at 150cm) |

| Camera (weight) | 725 g (25.57 oz) |

| Full assembly with Stand | 19.16 kg (42.24 lbs) |

| Electrical Characteristics | |

| Input voltage | DC 12V |

| Power consumption | 600mA operating |

| I/O Ports | |

| USB 3.0 Type A (Host) x 3 | |

| USB 3.0 Type C (Device) x 1 | |

| HDMI x 1 | |

| Ethernet port x1 | |

| Power jack port x 1 | |

| Performance Specifications | |

| Field of view | Horizontal 74°, Vertical 50° |

| Shape | Cubic, cuboidal and irregular shapes |

| Accuracy | d=1, less than ±1cm deviation / irregular d=2 |

| Measurement time | Less than 1 second |

| Texture | All opaque packaging, except very glossy and transparent. |

| Measurement surface | The background should have a contrasting color for items to be dimensioned, avoid over polished or glossy surfaces for best performance. |

| Indicator | Beep and LED |

| Environmental Specifications | |

| Operating temperature | 0°C to 40°C (32°F to 104°F) |

| Storage temperature | -20°C to 60°C (-4°F to 140°F) |

| Relative humidity | 0 to 70% relative humidity, non-condensing |

| Ambient light | 0 to 10000 lux, avoid direct sunlight |

| Sealing protection | IP42 |

Technological Innovation:

The Fixed Volume Measurement Scanner stands out with its advanced measurement capabilities, ensuring optimal packaging every time. It is designed to handle cartons, parcels, and irregularly shaped items, converting their dimensions into the minimum cubed measurements needed for efficient packing.

- Measurement Capabilities: Capable of accurately measuring diverse product shapes, ensuring no material is wasted.

- Configurable Measuring Methods: Offers four methods—automatic, manual, barcode scanner, and weighing scale—for flexible and adaptable use.

- Precision: Ensures every product is packed using the minimum necessary packaging, optimizing space and reducing costs.

Key Features:

- User-Friendly Setup: Quick assembly and minimal training required, getting your team up to speed rapidly.

- Real-Time Precision: Instant, precise measurements that facilitate quick and efficient packaging.

- Remote Configuration: Manage and monitor the scanner remotely through a web-based tool, integrating seamlessly into your operations.

- Enhanced Utility Kits: Optional tools such as a height-adjustable stand, weighing scale, and barcode scanner add to its versatility.

Unique Benefits:

- Adaptability to Various Product Shapes: The scanner’s ability to handle irregular shapes and convert them to minimum cubed dimensions optimizes packaging and reduces waste.

- Multiple Measuring Methods: The flexibility of using automatic, manual, barcode scanner, and weighing scale methods enhances operational adaptability and efficiency.

- Remote Management: The web-based tool for remote configuration and monitoring ensures seamless integration into existing workflows, enhancing operational efficiency.

The Fixed Volume Measurement Scanner is a game-changer for mid-sized businesses looking to enhance their packaging operations. Its precise measurements and flexible options provide a significant boost to efficiency, cost savings, and customer satisfaction.

3. Handheld Wireless Volume Measurement Reader: Versatility for Small Businesses

Small to medium-sized businesses often face the challenge of optimizing their packaging processes without the extensive resources available to larger operations. The Handheld Wireless Volume Measurement Reader is specifically designed to address these needs, offering a portable and robust solution that enhances efficiency and accuracy in packaging.

This versatile device ensures that every item is measured precisely, allowing businesses to make the most of their packaging materials and reduce shipping costs.

The Need for Versatility:

In small to medium-sized operations, flexibility and ease of use are crucial. Manual measurements can be time-consuming and prone to errors, leading to inconsistent packaging sizes and increased costs. Additionally, the lack of advanced measurement tools can hinder productivity and affect the overall efficiency of the packaging process.

The Handheld Wireless Volume Measurement Reader provides a practical solution by offering quick and accurate measurements in a portable format. This device is designed to be user-friendly and adaptable, making it ideal for businesses that require a flexible and efficient packaging solution.

Technical Specifications

| Physical Characteristics | |

|---|---|

| Dimension (W/D/H) | Device on Cradle: 120.0 W x 137.0 D x 204.4 H mm Device: 120.0 W x 83.0 D x 196.7 H mm Cradle: 119.9 W x 136.9 D x 92.1 H mm |

| Weight (g/oz) | Device on Cradle: 340g (11.99oz) Cradle: 210g (7.41oz) Total: 550g (19.4oz) |

| Electrical Characteristics | |

| Voltage Battery | Li-ion 3.7V/2600mA background |

| Power Consumption | Standby 230mA, Operating 490mA |

| Performance Specifications | |

| Field of View | Horizontal 52°, Vertical 30° |

| Shape | Cuboidal and irregular shapes |

| Accuracy | d=2, less than ±2cm deviation |

| Measurement Time | Less than 1 second |

| Object Size | Min. Cube: 10 cm / 0.394 inches cube (OIML 20cm cube) Max. Cube: 80 cm / 31.5 inches cube (OIML 60cm cube) |

| Color | All opaque packaging except black, very glossy and transparent |

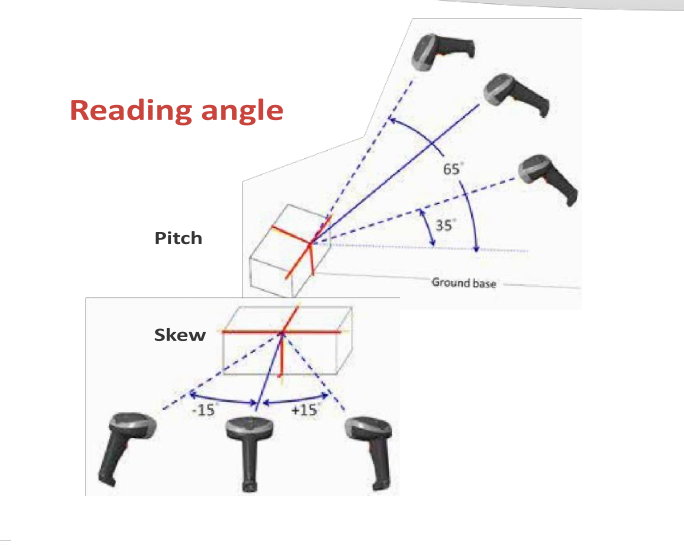

| Measurement Angle | Pitch: 35° ~ 65°, Skew: ± 15° |

| Measurement Surface | No black, transparent or very shining |

| Indicator | Beep and LED (Green, Red and Orange) |

| Aimer Specifications | |

| Wavelength | 650±10nm Red VLD IEC |

| Classification | 60825-1:2014 Class 1 |

| Environmental Specifications | |

| Operating Temperature | 0°C to 40°C (32°F to 104°F) |

| Storage Temperature | -20°C to 60°C (-4°F to 140°F) |

| Relative Humidity | 0 to 70% relative humidity, non-condensing |

| Ambient Light | 0 to 3000 lux, avoid direct sunlight |

| Sealing Protection | IP54 |

| Recharge Time | |

| Recharge Time | Approx. 5 hours |

| Reads per Charge | 4,000 times in 5 seconds duration, continuous reads in 5 hours. ** |

| Certification | |

| Certification | CE, FCC, LVD, OIML/MID certification, apply NTEP certificate |

| Radio Characteristics | |

| Bluetooth Module | Bluetooth V2.1 EDR |

| Frequency Band | 2.402GHz~2.480GHz |

| Transmission Range | Up to 80M (262.47FT.) line of sight in open space |

| RF Output Power | Class 1 (under 20dBm) |

| Tools and SDK | |

| Configuration Tool | Yes |

| Data Viewer Tool | Yes |

Technological Innovation:

The Handheld Wireless Volume Measurement Reader is a marvel of modern packaging technology.

06/19/2024

Its advanced features and compact design make it an invaluable tool for improving packaging efficiency and accuracy.

- Measurement Range: Capable of measuring items ranging from a minimum of 10cm cube to a maximum of 80cm cube.

- Accuracy: Provides precise measurements with a deviation of less than ±2cm, ensuring optimal use of packaging materials.

- Communication: Equipped with USB or RS-232 interface for easy data transfer and integration with existing systems.

Key Features:

- Portable and User-Friendly: The compact and robust design ensures that the device is easy to carry and use in various settings.

- Intuitive Reading Zone Detection: The device’s intuitive detection system simplifies the measurement process, making it accessible for all users.

- 3D Volume Measurement and 2D Barcode Reader: Offers comprehensive measurement capabilities, including the ability to read barcodes, enhancing its versatility.

- Fast Measurement Time: Measures items in less than 1 second, significantly speeding up the packaging process.

- Innovative Magnetic Power Connector: Ensures easy and efficient charging, with a high measurement frequency of 4,000 reads per charge.

Unique Benefits:

- Portability and Flexibility: The handheld design allows for easy use in various locations, making it ideal for businesses with limited space or mobile operations.

- Quick and Accurate Measurements: The device’s fast measurement time and high accuracy reduce the time spent on packaging and improve overall efficiency.

- Enhanced Versatility: The combination of 3D volume measurement and 2D barcode reading capabilities provides a multifaceted tool that can handle diverse packaging needs.

The Handheld Wireless Volume Measurement Reader is a versatile and efficient solution for small to medium-sized businesses looking to optimize their packaging processes. Its portability, accuracy, and ease of use make it a valuable addition to any packaging operation, helping businesses save time and reduce costs.

Section 3: A Look at the Benefits of the Advanced Ship-in-Multiple-Boxes Functionality

The Weight Conveyor Unit, Fixed Volume Measurement Scanner, and Handheld Wireless Volume Measurement Reader each bring unique strengths to the table. However, they also share several key benefits that collectively enhance packaging efficiency, cost savings, and overall operational effectiveness. Let’s explore these shared benefits and address potential concerns your target customer might have.

Universally Increased Efficiency

Automation Reduces Labor Costs: One of the primary advantages of integrating these tools is the significant reduction in manual labor. Automated measurement systems mean fewer employees are needed to manually measure and package items. This not only cuts labor costs but also allows staff to focus on more strategic, value-adding tasks. For businesses questioning the initial investment, the reduction in labor costs alone often justifies the expense.

Consistent Accuracy: Manual measurements are prone to human error, leading to inconsistent package sizes and potential waste. These advanced tools ensure precise measurements every time, which is crucial for maintaining efficiency and reducing waste. For those concerned about the reliability of automated systems, it’s important to note that these tools have been rigorously tested and certified to meet industry standards for accuracy.

Faster Order Fulfillment: Speed is critical in eCommerce. Integrating automated measurement tools significantly reduces the time spent on packaging, leading to quicker order processing and fulfillment. Businesses worried about meeting peak season demands will find that these tools help maintain high efficiency even under increased order volumes.

Cost Savings and Material Efficiency

Reduction in Shipping Costs: Accurate measurements lead to optimal packaging sizes, avoiding the use of oversized boxes that incur higher shipping fees. This is particularly beneficial for businesses dealing with high shipping volumes, as the cost savings on shipping can be substantial. If there are concerns about the cost-effectiveness of these tools, consider the long-term savings on shipping costs and how they can offset the initial investment.

Material Cost Savings: Efficient use of packaging materials is another significant benefit. By using only the necessary amount of material, businesses can reduce their packaging costs. This also supports sustainability efforts by minimizing waste. For eco-conscious businesses or those with sustainability goals, these tools align perfectly with reducing environmental impact.

Lower Return Rates: Properly packaged items are less likely to be damaged during transit, which reduces the incidence of returns and replacements. This not only saves costs associated with processing returns but also enhances customer satisfaction. Businesses worried about customer complaints and return rates will find that better packaging quality directly correlates with fewer damaged goods and happier customers.

Enhanced Operational Workflow

Streamlined Processes: The integration of these measurement tools streamlines the packaging workflow. Automated measurements and real-time data integration allow for seamless operations, reducing bottlenecks and enhancing throughput. For businesses facing operational inefficiencies, these tools offer a straightforward solution to streamline and optimize their packaging processes.

Improved Space Utilization: Efficient packaging means better use of warehouse space. Accurate measurements ensure that products are packed efficiently, freeing up storage space and enabling better inventory management. Concerns about warehouse space and inventory control are mitigated with these tools, as they help in organizing and maximizing the use of available space.

Scalability: These tools are designed to grow with your business. Whether you’re handling a few hundred orders or millions, the Weight Conveyor Unit, Fixed Volume Measurement Scanner, and Handheld Wireless Volume Measurement Reader can scale to meet increasing demands, ensuring consistent performance and efficiency. This addresses potential concerns about the tools’ ability to handle future growth and increased order volumes.

Customer Satisfaction

On-Time Deliveries: Integrating advanced packaging tools like the Weight Conveyor Unit, Fixed Volume Measurement Scanner, and Handheld Wireless Volume Measurement Reader significantly speeds up the packaging process. This ensures that orders are fulfilled more quickly and shipped on time, which is crucial for maintaining customer satisfaction. Businesses struggling with delays will find that these tools can help meet or exceed delivery expectations, keeping customers happy and loyal.

Enhanced Product Protection: Accurate and efficient packaging reduces the risk of damage during shipping. When products are measured and packed precisely, they are less likely to move around and get damaged. This not only minimizes the number of returns and exchanges but also enhances the overall customer experience. Concerns about product integrity during transit are effectively addressed with these advanced tools.

Sustainability Appeal: Consumers today are increasingly concerned about the environmental impact of their purchases. By optimizing packaging to reduce waste and using materials more efficiently, businesses can appeal to eco-conscious customers. This not only boosts brand reputation but also aligns with global sustainability goals. Companies looking to enhance their environmental credentials will find these tools invaluable in supporting their green initiatives.

Practicality and Ease of Use

User-Friendly Design: All three tools are designed with the end user in mind. They are easy to set up and require minimal training, making them accessible even to staff who are not tech-savvy. This ensures that the transition to automated measurements is smooth and hassle-free. For businesses worried about the learning curve associated with new technology, these tools offer straightforward interfaces and quick setup processes.

Flexibility and Adaptability: The tools are versatile enough to handle a wide range of products and packaging scenarios. Whether you are dealing with large, bulky items or small, irregularly shaped products, these devices provide accurate measurements and optimal packaging solutions. This flexibility makes them suitable for a variety of business models and operational needs, addressing concerns about their applicability in different contexts.

Reliable Performance: These tools are built to withstand the demands of high-volume operations. They offer reliable performance day in and day out, ensuring that businesses can depend on them for consistent results. This reliability is crucial for maintaining operational efficiency and ensuring that packaging processes run smoothly without unexpected disruptions.

Investment and Return

Fast ROI: While the initial investment in these advanced tools might seem substantial, the return on investment (ROI) is realized quickly through savings on shipping and material costs, reduced labor expenses, and fewer returns due to damaged products. Businesses considering the cost will find that the efficiency gains and cost reductions provide a compelling case for adoption.

Competitive Advantage: Utilizing advanced packaging optimization tools can provide a significant competitive edge. By reducing costs, improving efficiency, and enhancing customer satisfaction, businesses can position themselves ahead of competitors who rely on outdated, manual processes. For businesses looking to stay competitive in a rapidly evolving market, implementing these advanced solutions on platforms like Shopify and BigCommerce ensures they are at the forefront of efficiency and customer satisfaction.

Scalability for Growth: As your business grows, these tools can scale with you. Whether you’re expanding your product line, increasing your order volume, or entering new markets, the Weight Conveyor Unit, Fixed Volume Measurement Scanner, and Handheld Wireless Volume Measurement Reader can adapt to meet your needs. This scalability ensures that your investment continues to deliver value as your business evolves. These solutions integrate seamlessly, supporting your growth on platforms like Bigcommerce, Shopify, and more…

Section 4: Technical Insights into the Optimization Algorithm

The core of the Advanced Ship-in-Multiple-Boxes Functionality is its sophisticated optimization algorithm. This technology ensures that every product is packaged in the most efficient manner possible, balancing cost reduction, material savings, and enhanced customer satisfaction. Let’s delve into the mechanics of this groundbreaking technology.

Algorithm Mechanics

The optimization algorithm begins by taking precise measurements of the product’s dimensions and weight using advanced hardware like the Weight Conveyor Unit, Fixed Volume Measurement Scanner, or Handheld Wireless Volume Measurement Reader. Once the data is collected, the algorithm analyzes it in real-time, considering multiple factors such as product dimensions, weight, fragility, and shipping requirements.

- Data Input: The process begins with accurate measurements of the product’s dimensions and weight. This data is collected using advanced hardware like the Weight Conveyor Unit, Fixed Volume Measurement Scanner, or Handheld Wireless Volume Measurement Reader.

- Real-Time Analysis: The algorithm analyzes the collected data in real-time, taking into account product dimensions, weight, fragility, and shipping requirements.

- Optimal Packaging Configuration: By processing this information, the algorithm determines the optimal packaging configuration. This includes selecting the right-sized box and the appropriate amount of packing material to ensure product safety during transit.

- Output: The final output includes detailed packaging instructions that are easy for warehouse staff to follow, ensuring consistency and efficiency.

Factors Considered by the Algorithm

Several key factors influence the algorithm’s decisions. Accurate product dimensions and weight are crucial to avoid oversized boxes that increase shipping costs. The fragility of the product is also taken into account to ensure adequate protection.

- Product Dimensions and Weight: Accurate measurements ensure that the product is packed in the most efficient manner, avoiding oversized boxes that increase shipping costs.

- Fragility: The algorithm takes into account the fragility of the product to ensure that it is adequately protected during transit.

- Shipping Costs: By optimizing the packaging size, the algorithm helps in reducing shipping costs, particularly by avoiding dimensional weight pricing penalties.

- Material Usage: Efficient packaging minimizes the use of packing materials, reducing costs and environmental impact.

By optimizing the packaging size, the algorithm helps in reducing shipping costs, particularly by avoiding dimensional weight pricing penalties. Additionally, efficient packaging minimizes the use of packing materials, reducing both costs and environmental impact.

Machine Learning Integration

The optimization algorithm continually improves its accuracy and efficiency through machine learning. It adapts by learning from past data and packaging configurations, refining its calculations to improve future packaging decisions. By analyzing previous errors and inefficiencies, the algorithm adapts to avoid similar issues in the future.

- Adaptive Learning: The algorithm learns from past data and packaging configurations, continually refining its calculations to improve future packaging decisions.

- Error Reduction: By analyzing previous errors and inefficiencies, the algorithm adapts to avoid similar issues in the future.

- Trend Analysis: Machine learning enables the algorithm to identify and adapt to trends in product sizes, shapes, and shipping requirements, ensuring it remains effective even as product lines and shipping needs evolve.

Step-by-Step Process

- Scanning and Measuring: The product is scanned and measured using one of the advanced hardware tools.

- Data Processing: The collected data is fed into the algorithm for real-time processing.

- Packaging Instructions: The algorithm generates precise packaging instructions, including the optimal box size and the amount of packing material needed.

- Implementation: Warehouse staff follow the instructions to pack the product efficiently and securely.

This process ensures that packaging is always optimized, reducing costs and improving customer satisfaction.

Section 5: Optimizing Packaging for Leading eCommerce Platforms (BigCommerce, Shopify and More…)

Leveraging Advanced Ship-in-Multiple-Boxes Functionality Across Shopify, BigCommerce, Magento, and More…

eCommerce businesses today operate in a highly competitive landscape where operational efficiency and customer satisfaction are paramount. Platforms like Shopify, BigCommerce, and other major eCommerce platforms provide robust solutions for online retailers, but they often come with challenges related to packaging and shipping. The Advanced Ship-in-Multiple-Boxes Functionality is designed to seamlessly integrate with these leading eCommerce platforms, offering significant benefits tailored to their unique needs.

Shopify: Enhancing Fulfillment Efficiency

Shopify is a favorite among small to medium-sized eCommerce businesses for its ease of use and extensive app ecosystem. By incorporating the Advanced Ship-in-Multiple-Boxes Functionality, Shopify merchants can:

- Reduce Shipping Costs: Automatically determine the optimal box sizes, minimizing dimensional weight pricing and lowering shipping expenses.

- Improve Customer Satisfaction: Ensure products are well-protected and arrive in perfect condition, boosting customer loyalty and positive reviews.

- Streamline Operations: Seamlessly integrate with Shopify’s inventory and order management systems to enhance overall fulfillment efficiency.

BigCommerce: Scaling Up with Confidence

BigCommerce is known for its scalability and flexibility, making it ideal for growing businesses. The Advanced Ship-in-Multiple-Boxes Functionality supports BigCommerce retailers by:

- Scalable Solutions: Handle large volumes of orders with the Weight Conveyor Unit, ensuring fast and accurate packaging.

- Cost-Effective Packaging: Use the Fixed Volume Measurement Scanner to minimize material usage and reduce operational costs.

- Enhanced Integration: Easily integrate with BigCommerce’s advanced features, such as multi-channel selling and customizable shipping options.

Other Platforms: Versatility and Adaptability

Beyond Shopify, BigCommerce, and Magento, the Advanced Ship-in-Multiple-Boxes Functionality is adaptable to other eCommerce platforms like WooCommerce, 3DCart, and Volusion. These platforms benefit from:

- Flexible Integration: Adapt to various platform requirements with customizable settings and interfaces.

- Universal Benefits: Achieve cost savings, enhanced efficiency, and improved customer satisfaction regardless of the platform used.

The Advanced Ship-in-Multiple-Boxes Functionality represents a transformative approach to eCommerce packaging. By integrating cutting-edge algorithms and state-of-the-art hardware, this solution addresses critical inefficiencies in the packaging process, delivering substantial benefits to businesses of all sizes.

Optimize, Save, Thrive and Succeed

Every dollar saved on shipping and materials can directly impact the bottom line, and the advantages of this solution are clear. The Weight Conveyor Unit, Fixed Volume Measurement Scanner, and Handheld Wireless Volume Measurement Reader collectively provide precise measurements, automate tedious tasks, and ensure optimal packaging configurations. This results in reduced shipping costs, minimized material waste, and enhanced operational efficiency.

Businesses that adopt these advanced technologies can expect to see:

- Significant Cost Savings: Reduced shipping and material costs translate to immediate financial benefits.

- Improved Operational Efficiency: Automated measurements and optimized workflows free up valuable resources, allowing staff to focus on more strategic activities.

- Enhanced Customer Satisfaction: Better-protected packages and faster delivery times improve the customer experience, fostering loyalty and repeat business.

- Sustainability Gains: Efficient packaging practices reduce waste, supporting environmental sustainability and enhancing your brand’s reputation among eco-conscious consumers.

Take the Next Step Towards Optimizing Your Processes

Now is the time to revolutionize your packaging process. By implementing the Advanced Ship-in-Multiple-Boxes Functionality, you position your business to reap the benefits of advanced technology, drive operational efficiencies, and enhance customer satisfaction.